I've made some progress last weekend and this one (had a lot going on at work in the interim)...

Power is now mostly wired up. I say mostly because the kit came with a faulty switch, which I had hooked up as the standby. Whilst testing continuity, I discovered that the switch read infinite ohms in both positions, so I pulled it to isolate it, and sure enough, it refuses to pass a signal in either position. This is unlike the other switch which works great. Radio Shack just had crappy plastic junky switches, so I let Stephen know about this, and another switch is on its way (Thanks Stephen!).

I also got all the PT hookups done, and wired up the OT to the power tube sockets. The rectifier is now done, and the tube sockets are all done, save for the connections that will come from the board.

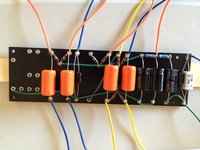

My son and I have been working steadily on the board. We have about 2/3 of the board finished now, with the notable exception of the .02µF orange drop cap (more on that in a bit). So far I'm pretty happy with the soldering we've done, except for one that I think we got too hot, as the 1 Mega-ohm resistor (which correctly measured 1M-ohm before install) now measures considerably higher at 1.48 Mega-ohms...

So we may need to pull that one and get a new one and re-do that whole solder eyelet... What would cause an increase in resistance like this? Is it really possible that I "cooked" the resistor?

Anyway, here's the board as we have it so far:

Attachment:

File comment: Board progress...

IMG_0009_2.jpg [ 1008.03 KiB | Viewed 21854 times ]

IMG_0009_2.jpg [ 1008.03 KiB | Viewed 21854 times ]

Now, as to the .02µF cap, the reason we haven't wired that up yet is because the cap I have reads 2.22 nF. Now I know my math isn't great, but I'm pretty sure that would be .002µF, not .02µF... I double-read the layouts and the schematic, and it really does appear that it need a .02µF, so unless I'm missing something obvious, I was shipped the wrong cap... The markings on the cap show "SBE 715P 600V" on one line and "222J 0732" on the next line. If I'm reading that right, then the "222J" part means 22*100pF == 2200pF == 2.2nF == .0022µF, which is exactly what I'm reading with the multimeter, so it really does seem like I was shipped the wrong cap. When I went through and took inventory of the kit that was shipped to me against the BOM, I saw .022µF/600V, and saw the "22" and "600V" on the cap, and assumed it was right. I should have measured them all (although everything else other than the switch seems to have been right). I've notified Stephen, and hopefully he'll be patient with me...